Single vs Twin Cylinder Steelworkers: Which Configuration for Your Workshop?

Single cylinder steelworkers perform one operation at a time – punch, then move to shear, then notch. Twin cylinder configurations let you run two stations simultaneously – punching whilst shearing, for example. The difference isn’t about capability or tonnage; it’s purely about workflow efficiency and whether you can keep the machine busy enough to justify the higher purchase price.

Most workshops assume twin cylinder means “better,” but the reality is more nuanced. For many small to medium fabricators, the extra investment never pays back because operators can’t keep both cylinders working simultaneously. Understanding which configuration actually suits your production patterns prevents expensive over-specification.

Understanding Single vs Twin Cylinder Configurations

The “cylinder” refers to the hydraulic power units that drive the steelworker’s various functions. A single cylinder steelworker has one hydraulic pump and operates one station at a time. Twin cylinder machines have two independent hydraulic systems, allowing simultaneous operation at two different stations.

This doesn’t mean single cylinder machines are slower at individual operations. Both configurations punch, shear, and notch at the same speed for their tonnage rating. The speed difference only appears when you need to perform multiple different operations on the same batch of material – twin cylinder lets two operators work simultaneously whilst single cylinder means operations happen sequentially.

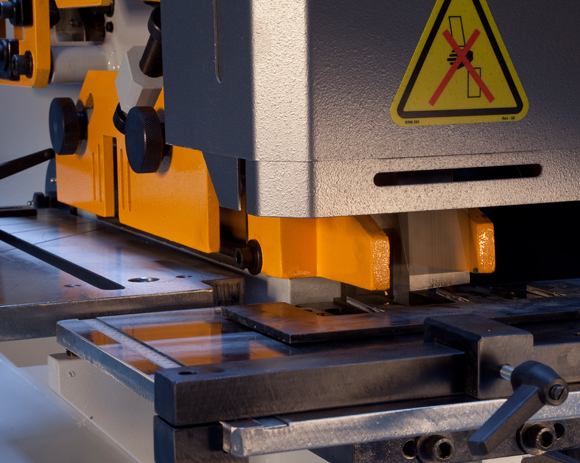

AFM Europe stocks both configurations from premium manufacturers including Kingsland steelworkers, known for robust build quality, and Geka ironworkers, favoured in structural fabrication.

How Each Configuration Works in Practice

Consider a typical structural steel job: punching bolt holes in angle iron, then shearing to length, then notching the corners. With a single cylinder steelworker, you punch all the holes, move to the shear station and cut all the pieces, then move to the notcher and finish the batch.

With twin cylinder, one operator can punch whilst another shears the previously punched pieces. The operations overlap rather than waiting for each other, potentially reducing cycle time by 25-30% on repetitive batches.

However, this only works if you have two operators and consistent workflow where both stations stay busy. If one operator is working alone, the twin cylinder offers no advantage – they’re still moving between stations sequentially. The second cylinder sits idle, which means you’ve paid extra for capacity you’re not using.

When Twin Cylinder Justifies the Investment

High-volume structural steel fabrication suits twin cylinder configurations well. Workshops producing repetitive structural components – stair stringers, roof trusses, trailer frames – can establish efficient two-operator rhythms where both stations run continuously. In these environments, the productivity gain typically delivers measurable payback.

Multiple shift operations also favour twin cylinder. When you’re running two or three shifts, having that simultaneous capability means each shift can maintain higher throughput. The machine utilisation increases enough to justify the investment.

Production environments where quick turnaround matters – job shops quoting tight delivery times, maintenance contractors handling emergency work – benefit from the flexibility to throw two operators at urgent jobs when needed. The key is honestly evaluating whether your workflow patterns can genuinely utilise both cylinders simultaneously, rather than paying for capacity that sits idle.

When Single Cylinder Is Perfectly Adequate

Single operator workshops get no benefit from twin cylinder configuration. If you’re the only person running the steelworker, you can only operate one station at a time regardless of how many cylinders the machine has. The smart choice often involves selecting premium used machinery over new, preserving capital whilst meeting actual production needs.

Light to medium fabrication work – general engineering, repair workshops, agricultural fabrication – typically doesn’t generate enough volume to keep both cylinders busy. You might punch and shear twenty pieces weekly rather than two hundred. Single cylinder handles this workload perfectly well.

Budget-conscious buyers should consider that a quality used single cylinder steelworker often delivers more practical value than a new twin cylinder at similar cost. The saved capital stays in your working capital for materials, wages and other equipment needs.

Price Difference and Used Market Availability

Twin cylinder steelworkers command a premium over equivalent single cylinder models at the same tonnage rating. This price gap persists across all tonnage ranges and reflects the additional hydraulic system and controls required for simultaneous operation.

In the used machinery market, single cylinder machines are considerably more common. Most workshops buy single cylinder initially, which means that’s what appears on the used market. Twin cylinder machines do become available but less frequently, and they hold their value better because buyers recognise the productivity potential.

For workshops considering used equipment, this creates an opportunity. A well-maintained used single cylinder steelworker from premium manufacturers like Kingsland or Geka delivers the capability you need at a fraction of new twin cylinder cost – provided you genuinely don’t need simultaneous operation.

Making the Right Choice for Your Workshop

Start by honestly assessing your actual production patterns, not theoretical future needs. How many hours daily does your steelworker actually run? Could you genuinely keep two operators busy at different stations simultaneously, or would the second operator spend half their time waiting?

Calculate the productivity gain realistically. If you currently spend significant time monthly on steelworker operations, twin cylinder might reduce that by 25-30%. What’s that time worth to your business? Does it justify the additional investment? Sometimes yes, often no.

Consider your growth plans practically. Many buyers over-spec thinking “we might need it in two years.” But if you’re genuinely growing fast enough to need twin cylinder capacity soon, you can upgrade then. Meanwhile, starting with single cylinder preserves working capital and proves the market before you invest in higher capacity.

At AFM Europe, we stock both new steelworkers and used steelworkers and corner notchers in single and twin cylinder configurations. Our recommendations aren’t biased toward one type because we carry both – we match the machine to your actual workflow rather than pushing higher-spec equipment you won’t fully utilise.

Choosing Based on Workflow

The single versus twin cylinder decision isn’t about which is “better” – it’s about which matches your actual production patterns. Most workshops operate perfectly well with single cylinder because they don’t have consistent two-operator workflow or sufficient volume to keep both cylinders busy.

Twin cylinder makes excellent sense for high-volume structural fabrication with multiple operators or shifts. For everyone else, single cylinder delivers the capability you need whilst preserving capital for other business priorities. The smart choice comes from honest assessment of how you actually work, not how you imagine working someday.

Evaluating steelworker configurations for your workshop? Browse our range of new steelworkers and used steelworkers and corner notchers, or contact our team to discuss which configuration actually suits your production patterns. We’ll help you match equipment to reality rather than selling you capacity you won’t use.