How Can Flat Bed Fibre Laser Cutters Improve Productivity?

Unlocking New Levels of Productivity with Flat Bed Fibre Laser Cutters In the fast-paced world…

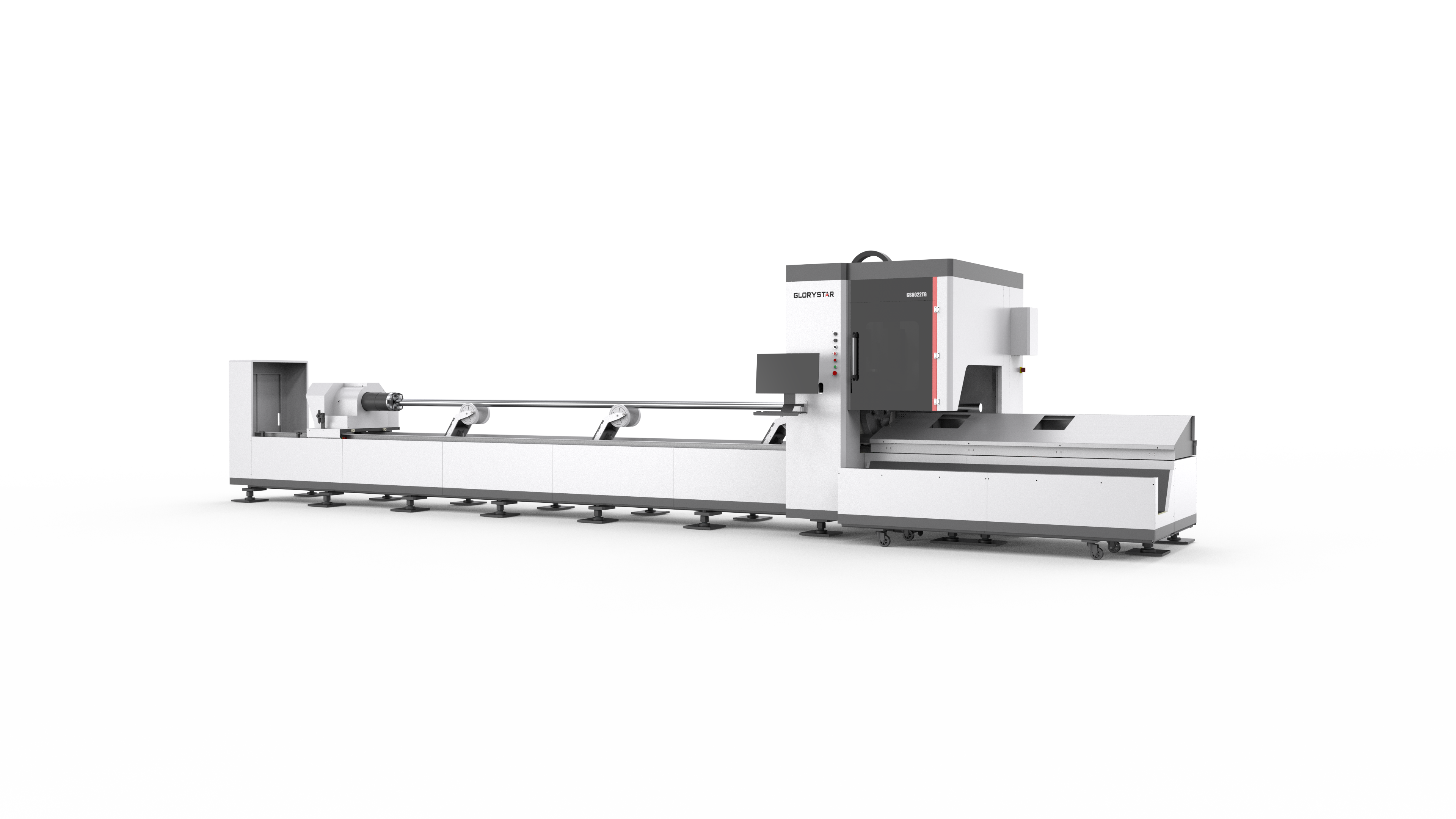

Discover cutting-edge metal-cutting solutions with our high-performance fibre laser machinery. As seasoned experts in the field, we at AFM bring extensive experience in supplying and installing Fibre Lasers, making us your ideal partner. Our fibre laser machines, also known as fiber lasers, are specialized tools designed for the precision cutting of mild and stainless steel, along with other non-ferrous metals. Powered by advanced fibre-optic laser sources, these machines ensure unrivalled reliability, speed, and accuracy. Explore the versatility of CNC Fiber laser machines, which can be easily configured to cut even the thickest sheet metals. Our exclusive partnership with Glorystar has provided AFM with a brand new fleet of High Quality Fiber Laser machinery. With both Fibre laser flat bed and tube cutting machines available for demonstration in our dedicated showroom. Get in touch today to discuss your needs with one of our Fibre laser machinery specialists!

Tube laser cutting machines are an exceptional solution to cutting a variety of tubular profiles and sections of various lengths, wall thicknesses and materials. Fibertube, our specialist Fiber laser tube cutters from Ermaksan provide fully automatic pipe cutting with an automatic pipe loading section. Our fibre laser cutting technology cuts pipes with a precision level of microns and minimizes waste. Our laser tube cutters offer high dynamic control combined with uninterrupted continuous cutting processes thanks to our specialist smart factory Industry 4.0 software and automatic loading units. Get in touch today to discuss your needs with one of our Fibre laser machinery specialists!

Fibre laser Cutters are advanced machines used in Precision cutting jobs, they play a crucial role in metalworking workshops. Fibre laser cutters can be used to process a wide range of metals including Steel, Aluminium, Copper and brass, Titanium and nickel alloys and more.

Fibre laser cutters are used in sheet metal and production workshops and generate a laser using optical fibre, which is then directed onto the material to be cut. Fibre laser machinery is renowned for its speed, accuracy and versatility. Fibre laser cutting machines can be used to cut materials other than metal too, including some plastics and Composites.

Before cutting, the metal sheet or workpiece is prepared by cleaning it surface and placing it on the Laser cutting bed or worktable. The cutting parameters, including path, speed, power, and focus are all programmed into the CNC system of the fibre laser cutter. This is usually done using CAD/CAM software, which allows for precise control and customisation of cutting design.

Fibre laser cutters operate by generating a high-energy laser beam within an optical fibre. This beam is then focused onto the metal material to be cut, heating and melting it along the programmed cutting path. Gas, such as oxygen or nitrogen, assists in blowing away debris for clean cuts. Systems for cooling the laser and extracting fumes ensure a safe work environment. Throughout the process, cutting parameters are monitored to ensure precise cuts meet specifications.

All of our fibre laser cutters will cut mild/carbon steel. How thick you can cut is depend on what power source you choose.

Cutting stainless steel with one of our Glorystar or Fibermak laser cutters is easily achievable and at high accuracy.

If you’re looking to process aluminium on a fibre laser cutter, we can advise you on the best possible cutting solution for this reflective material.

Titanium plate can be cut using our Glorystar and Fibermak fibre laser cutters*. When looking to cut titanium plate, adjustments will need to be made to the assist gasses and the nozzle used during the cutting process.

Due to the high reflectivity of brass and copper, alterations will need to be made to the power and speed settings. Anti reflection optics will need to be used to protect your laser’s internal components from the laser light.

Unlocking New Levels of Productivity with Flat Bed Fibre Laser Cutters In the fast-paced world…

Efficiency Meets Sustainability Modern manufacturing isn’t just about output—it’s also about responsibility. As energy costs…

In the world of metal fabrication, investing in the right machinery can make all the…