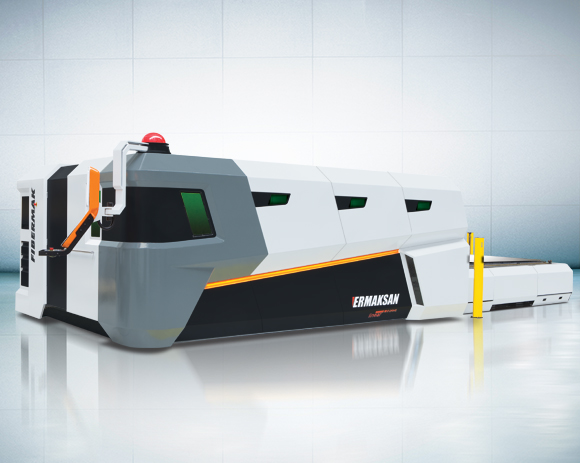

Description

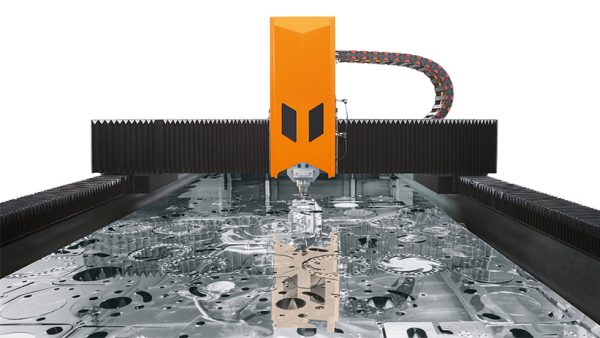

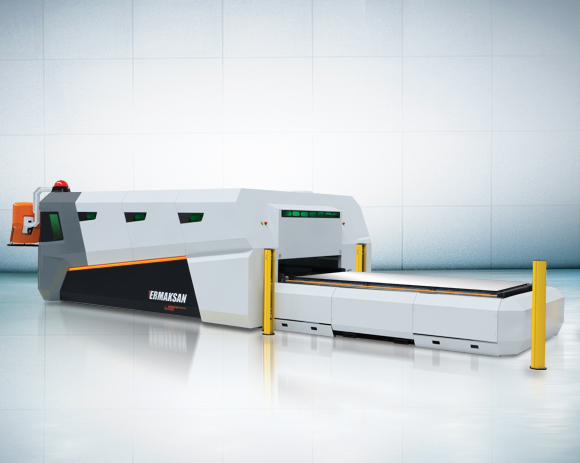

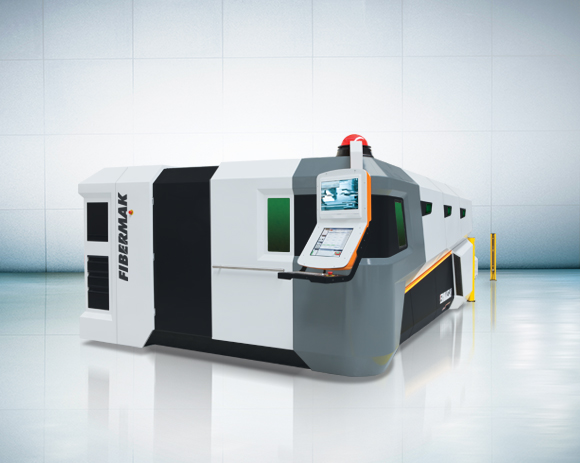

Brand new stunning design, improved ergonomics for optimized work flow, flawless cut quality, high efficiency and high cutting capacity, we introduce the new Fibermak.

FIBERMAK G-Force

The new fibermak G-Force is desgined with the servo motor concept in mind, allowing acceleration of 4G. thanks to its high acceleration between parts, efficiency is increased on average by 15% per hour

Customer benefits

- %70 energy saving and high productivity.

- 3 times faster thin material cutting.

- Low invesment costs.

- Ergonomic details.

- Fly-cut technology.

- Filexibility to cut different types of material.

- 2-3 times more part cutting with 24 hours mass production.

- Less production costs than your competitor.

- Lantek Expert Cut CAD/CAM software.

- Thousands of machines working all around the world.

- Pipe cutting system.

- Durable choice for your precise cutting works.

- StorEasy shelves:

Designed for easier access to your nozzles, lenses and more. - Controller:

Fast, ergonomic, user friendly controller with 17’’ touch LCD color screen. Dual screen configuration shows all the controls you need in one while providing live video feed from inside the cutting area on second. - Sliding roof:

Designed to provide easier access. - Protective windows:

Eyes are always safe with special coated filters. - Sliding front door:

Redesigned to allow easier access and maintenance. - Rigid structure:

The strongest frame ever built with precise manufacturing techniques providing dynamic and static stiffness. - New safety standards:

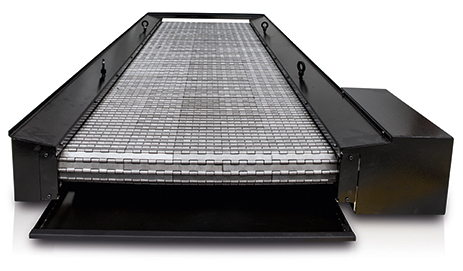

SICK Photocell safety system standard, conforming to European and N.American safety standards. - Automatic pallet changer:

Dual pallet changer standard for more efficient production runs.

Fast, Accurate, Smooth;

Ermaksan’s high-tech fiber laser cuts mild steel up to 20mm thickness with maximum precision and exceptional quality in a fast paced manufacturing environment.

WHY FIBERMAK ?

- Up to 3x faster cuts with FlyCut technology. Axes equipped with linear motors and drivers reach to 141 m/min. speed and accelerations are 2 G on Y, 2 G on X axes.

- Fiber laser is a green technology saving a minimum of 50% electricty compared to CO2 lasers.

- There is no need for optical components as laser transmitting is done by fiber cable.

- There is no need for components such as beam path, folding mirror, quartz tube, bellows and turbo blower etc..

- Extended cutting possibilities of reflecting materials such as aluminum, copper, brass etc. by enabling precise cuts and smooth surface quality.

- Heavy-duty constructed FIBERMAK frame, equipped with worldwide well known, long-lasting, high-quality components is designed to work accurately and continuously even in hard conditions. High Reliability High Efficiency High Quality Main Features:

- Excellent Beam Parameter Product (BPP)

- Constant BPP Over Entire Power Range

- Small Focus over Large Working Distance

- Over 30% Wall-Plug Efficiency

- Maintenance Free Operation

- Modular ‘Plug & Play’ Design

- Compact, Rugged & Easy to Install

- Estimated Diode Lifetime up to 100,000 hours

- Integrated Coupler or Beam Switch

High Efficency

High Quality

General Features:

- Excellent Beam Parameter Product (BPP)

- Constant BPP Over Entire Power Range

- Small Focus Over Large Working Distance

- Over 30% Wall-Plug Efficiency

- Maintenance Free Operation

- Modular “Plug & Play” Design

- Compact, Rugged & Easy to Install

- Estimated Diode Lifetime up to 100.000 hours

- Integrated Coupler or Beam Switch

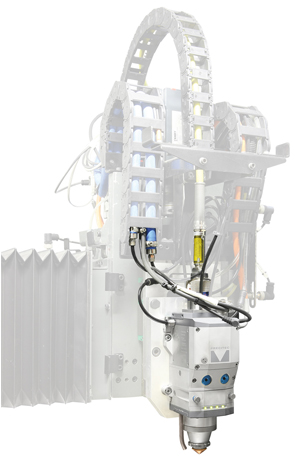

PRECITEC PROCUTTER 2.0 CUTTING HEAD

The new ProCutter 2.0 generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring – this is how laser cutting is shaping up in the new generation, due to numerous developments.

The reliability and power capability has been perfected – up to the maximum laser power of 15 kW. By default, the ability to exchange the nozzles automatically is now provided. Automated piercing with the PierceTec technology package ensures a fast, clean and reproducible process. Due to direct water cooling (CoolTec) of the sheet metal, permanent stable mild steel cutting is possible.

- motorized focus position adjustment for automatic machine setup and piercing work

- lightweight and slim design created for fast acceleration and cutting speed

- drift-free, fast-reacting distance measurement

- permanent protective window monitoring

- automated piercing with PierceTec

- water cooling of the sheet metal with CoolTec

- completely dustproof beam path with protective windows

- LED operating status display

- output of all sensor data via WLAN to APP and machine control possible

- pressure monitoring in the nozzle area (gas cutting) and in the head

CAD/CAM

Lantek Expert

FIBERMAK uses Lantek Expert Cut Cad/Cam Software by its own postprocessor. There are many features to make cut easier like a automatic nesting and machining, calculation of time/cost, micro-joint, common cut… etc.

All cutting Data has been installed Lantek’s Tables of Technology Part. Thus, part program which is made a nesting and machining is directly installed to the CNC without any cutting parameter settings. Lantek has also some additional features if it is not able to cut like a smaller hole (0,5 x thickness of material) Lantek decides automatically marking.

Easy Programming Features

- Cutting Technology Charts according to material types and thicknesses

- Automatic nesting + processing

- Time and cost calculation

- CAD module

- Micro-joint

- Common cutting

- Film burning

- Automatic I/O