Description

Strong mono-blok rigid O type body built up by stress relieved welded steel construction has high acceleration axes. Sheet processing can be done multi-directional and flexible until 6 mm thickness on ETP Turret Punch Press.

Hydraulic, electronic, electric and mechanic components that are respected with its high quality worldwide have been used on the machine.

Machine has been equipped with hdyraulic, electronic, electrical and mechanical parts which has been adopted around world with their quality.

Customer benefits

- It designed to decrease learning time to the minimum.

- It allows users to produce parts on the first day with its simple and user friendly menü guide.

- It decreases, data input significantly by using perfect auto complete.

- Including it choose the most proper sheet, It decreases amount of material of skeleton by using perfect auto nesting.

- It decrease preperation time with full automatic tools.

- Durable choice for your precise cutting works.

- Easy installatıon and training.

EASY TO LEARN

- Designed to reduce learning time to a minimum.

- Simple, user-friendly menus guide users at all times, enabling them to produce parts from the first day.

INTEGRATION

- Integrates part design, nesting and manufacturing technology in just one programme. This integration reduces the time and effort required to generate numerical control programmes.

BENEFITS

- Excellent integration reduces data entry significantly.

- Excellent nesting features including best sheet selection reduces scrap.

- Excellent costing and timecalculation including all consumable and raw material, improves efficiency and allows accurate scheduling.

- Integration into the sheets database allows efficient tracking and control of inventory.

- Advanced machining options allow for very efficient machining.

- Fully automatic tooling saves on setup times.

- Three pieces of sheet holder clamp operating with pneumatic pressure and pinching sheet without causing any deformation thanks to spherical shaped holders.

- Clamp safety check system prevents collisions between clamps and tools by comparing the clamps positions with part program.

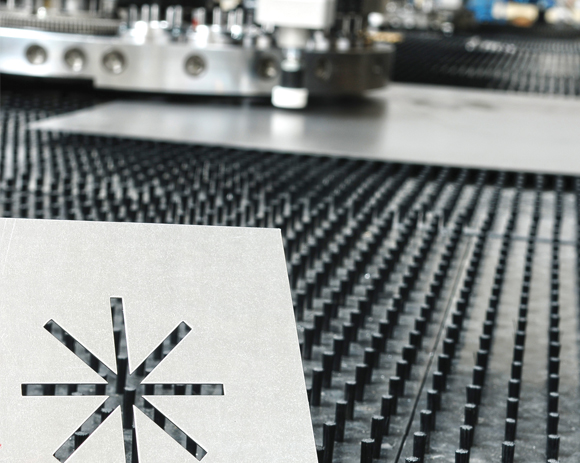

- A sheet plate with 2500 x 1500 mm dimension processing big table and brushed and/or ball bearing type table for easy sheet feeding.

- Interpolation of sheet weight – acceleration by CAD/CAM (CNC controlled automatic axis acceleration calculation according to the sheet thickness and dimensions while CAD is being prepared).

- Sensitive linear bearing equipments, guides without gap, sensitive screw axles and dynamic servo motors, intelligent drivers are used on X and Y axes.

- The dynamic buffer designed with these equipments does not make a concession from its sensitivity even at high accelerations.

- Punched parts automatically being transferred to outside of working area.

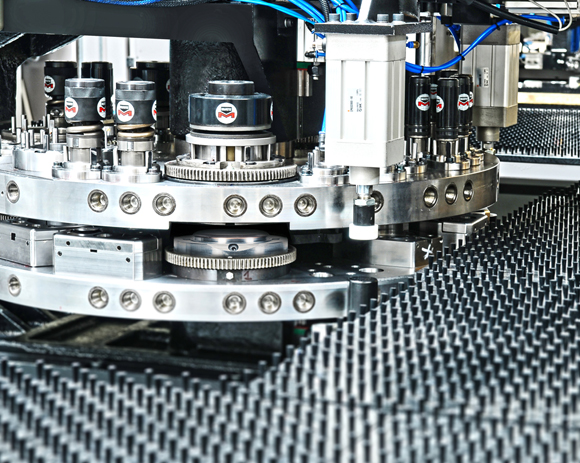

Thich Turret type Wilson or Mate brand high quality tools in 33 stations, 3 of them indexable D stations may include 8A or 3B or 1C stationed tools upon to your request.

Thus the tool quatity may be increased up to 54.

Hardened steel coated tool adaptor system assures maintenance free long life-time working.

Many operations are possible to make as forming with functional tools, perforating various diameters and special evacuating.

TURRET (33 STATION) Tooling Permutation:

15 x A station 1/2” fixed 1,6-12,7 mm round

12 x B station 1-1/4” fixed 12,8-31,7 mm round

2 x C station 2” fixed 31,8-50,8 mm round

1 x D istation 3-1/2” sabit 50,9-88,9 mm round

3 x D station 3-1/2” indeks 50,9-88,9 mm round

SPEED And ACCURACY

- Maximum punch stroke for 1 mm step movements on X and Y axes processing 1 mm thick mild steel is 1100 per minute and marking speed is 1800 stroke/min. X + Y dependent velocity 120 m/min.

- Positioning accuracy is ± 0,05 mm.

AUTOMATIC INDEX STATIONS

- Different contours at required angles can be cut with 3 pieces automatic index stations. These stations may include 8A or 3B or 1C stationed tools upon to customers request and so wide range of tooling combinations are possible.

- Index positioning accuracy is 0,01°

HDDL HYDRAULIC SYSTEM

- Optimized adjustable movement gap according to cutting necessities for different applications as punching, forming, soft punching and marking etc.

- Stroke configurable punch pattern feature for different punching functions.

- Intelligent punching pressure.

- No wearing and maintenance free punch cylinder system.

AIR BLOW

- Provides automatic tool lubricating and extends tool life-time.

- Avoids return up of scraps and heating up of tools during working.

CONTROLLER:

Fanuc 31i-P

- Part program memory, 256 kb

- Memory C, FROM / SRAM, 16 mb / 1 mb

- CP