Description

Ermaksan combining its 30 years press brake manufacturing experience with latest technologies, presents new generation Evolution series hybrid press brakes.

Fast, silent, precise, environmentally friendly and energy saving EVOLUTION series press brakes provides faultless bending of small parts even at different points by its high repetition and bending precision features.

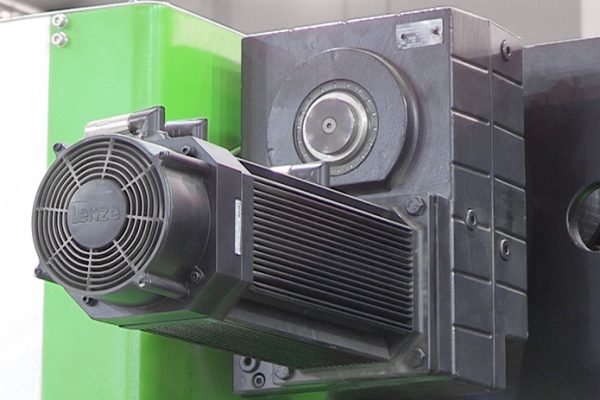

Hydraulic pistons are being driven by AC servo motors without proportional direction valves on Evolution series hybrid press brakes. There is no need for positioning valves resulting in excellent precision and less maintenance. Whilst the pump is working continuously on an ordinary press brake, there is only energy consumption when the operator pushes the foot pedal and moves the top beam for bending on Evolution series hybrid press brakes. As there is no pressure loss, energy i.e. bending power is at highest level. Oil level is also reduced by 80%. there is no oil heat up and the oil has long life-time

Environment friendly

ERMAKSAN’S Evo III new generation hybrid press brake is the best environment friendly produced press brake so far with a %60 energy saving.

Customer benefits

- The most economic with %60 energy-saving.

- The fastest with 20 mm/sn bending speed.

- The most precise with +/- 0,01mm bending repetition.

- The most environmentally friendly with 18 litre oil capacity and 5 years oil life.

- The quietest with 69 dB noise level.

- 17” 3D touch screen LCD Delem DA-66T.(other controllers are available)

- Easy installation and training.

Advantages

- Near silent working (63dB). one of the quietest sheet metal bending machines.

- Minimum 60% average active energy save and energy loss minimized sheet metal bending machine.

- Energy consumption:

– 95% less while standing ready for bending

– 95% less while free fall movement of the beam

- Minimum 50% less while bending. When the thickness of sheet decreases, energy save increases.

- Furthermore when the part has been bent, energy consumption reduces immediately.

- As the oil doesn’t heat up,the bends remain extremely accurate.

- High bending precision 0.01 mm.

- Faultless bending of small parts even at different points.

- 80% less oil volume and less frequent oil changes. Moreover there is no need to change oil for at least 5 years.

- 3 times longer life-time for hydraulic system and pump. due to only being active whilst bending.

- There is no continuous oil circulation as the pump doesn’t work all day, thus the oil doesn’t heat up.

- Bending power is at highest level by no pressure loss as there are no proportional valves.

- Y1 and Y2 axes have independent oil tanks. Thus, the maintenance will be realized at only one side if any brake-down appears. Therefore, servicing will be easier.