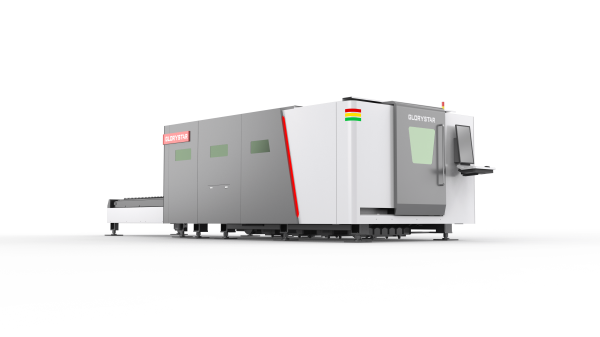

Description

The machine can be equipped with a power source from 1.5kw up to 30kw. Panasonic motors and drives for the X & Y axis, as well as ethercat technology results in fast acceleration, fast positioning speeds and fast cutting times.

The control is by Cypcut and includes software for drawing parts or importing DXF files.

High Speed

Using industry-leading servo motors, offering high positioning speeds of 120m/min helping you achieve higher production efficiency and output in a shorter time.

High Precision

High Precision ball screws and linear guides help to achieve a positional accuracy of +or- 0.03mm, and a consistent cut quality.

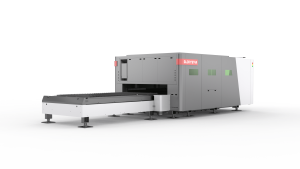

| Dual Shuttle Table:

The machine maximises uptime with an integrated shuttle table system that allows one table to be loaded/unloaded while cutting on the other table. Table changeover is complete in just 14 seconds on our 3 x 1.5m model. |

|

| Powerful Dust Removal System:

Automatic zoning dust removal, effectively removes dust, debris and smoke during the whole cutting process. Safe and environmentally friendly. |

|

Cutting Capacity

| 1500W | 2000W | 3000W | 4000W | 6000W | |

| Stainless Steel | 1-6mm | 1-8mm | 1-10mm | 1-14mm | 1-25mm |

| Aluminium | 1-4mm | 1-6mm | 1-8mm | 1-10mm | 1-20mm |

| Carbon Steel | 1-16mm | 1-18mm | 1-22mm | 1-22mm | 1-30mm |

| Brass | 1-3mm | 1-5mm | 1-6mm | 1-8mm | 1-12mm |

| Name | Brand | Performance advantage | |

| Laser Source | RAYCUS/MAX PHOTONICS | Excellent beam quality under high power, with large surface area/volume for gain cut-off, inherent fully enclosed flexible optical path, maintenance-free optical path, single junction diode (pump optical module); over 100,000 hours of service life, small size Light weight, easy integration, high output power, water and electricity saving and cost saving. |  |

| Laser Cutting Head | Glorystar/BLT | Automatic focusing to improve cutting efficiency whilst ensuring Stability and reliability;

Servo motor is used for focusing, the focus stroke is large, and thick plates can be cut |

|

| Software System | FSCUT | Strong compatibility, with advanced function modules such as capacitor edge seeking, electric focusing, plate/ tube cutting, fly cutting, leapfrogging, compensation, power-off memory, etc. |  |