Description

ERMAKSAN’s reliability, superior product quality & high production technology meets the needs of an ever-changing world whilst providing developing technologies as flexible solutions to customers every day.

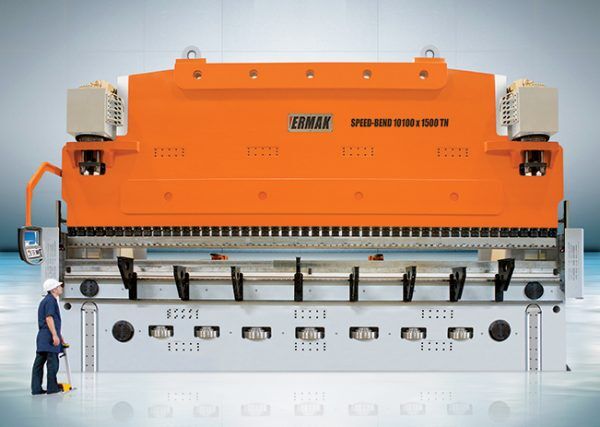

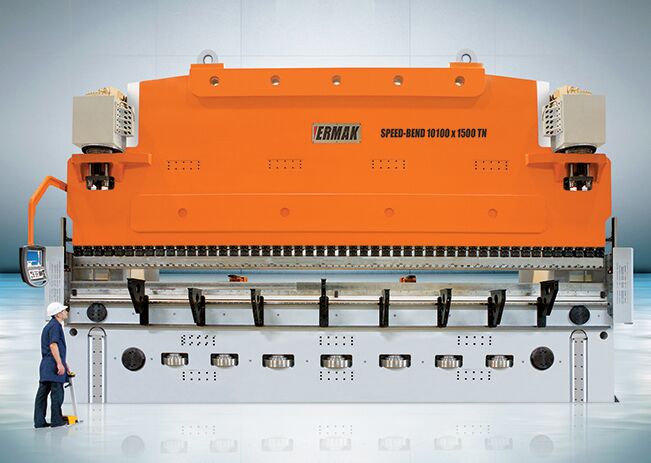

ERMAKSAN Heavy Duty Press Brakes meets the needs of all sectors engaged in the production of heavy machinery such as transportation, wind turbines, power plants, and the defense industry.

ERMAKSAN Heavy Duty Press Brakes eliminate labor and time losses whilst providing flexible solutions to all the needs of the industry.

The right choice for deeper and more powerful bends;

ERMAKSAN Heavy Duty Press Brakes allow you to work to the maximum capacity of your organization, and puts an end to time-consuming and costly production.

ERMAKSAN Heavy Duty Press Brakes allow you to work to the maximum capacity of your organization, and puts an end to time-consuming and costly production.

Customer benefits

- 17” 3D, LCD touch screen ER-90 (other options available Cybelec, Delem)

- Perfect configuration for your heavy tonnage bending.

- Absolute solution for deep and full-sized bending.

- Continuous precision with dynamic crowning system.

- 6 axis servo motor back gauge system(O).

- AP3 / AP4 front sheet support system(O).

- Special top and bottom tools(O).

- 610mm throat depth.

Solutions for heavy duty bends;

ERMAKSAN Heavy Duty Press Brakes with its standard specifications can handle deeper and longer plates with maximum accuracy and quality.

ERMAKSAN Heavy Duty Press Brakes with its standard specifications can handle deeper and longer plates with maximum accuracy and quality.

General features

- Chrome covered cylinders are machined with 0.001 mm and pistons are specially stiffened.

- Front support arms are slide-able along the full machine length and easy to adjust.

- Compact and world wide recognized HOERBIEGER hydraulics are fitted, giving excellent bending results.

- Two photocells on sides for rear guard.

- Fast tool tightening.

- Optic linear scales are sensitive up to 0.001 mm.

- Hanging and mobile control unit on a pendant arm allows the operator to work at both ends of the machine.

- HEIDENHAIN linear scales.

- Scaled in metric, height adjustable front support arms.

- SIEMENS electrical system.

- Synchronized working cylinders will give you the best bending result with its perfect repeat ability ratio.

- 2 axis ultra strong back gauging system (X=800 and R), with 0.01 mm repeat ability moves along rails and ball screw, bending length controlled by CNC controller, fold-able back gauge fingers for reverse bending applications.

- 2 axis (X, R), 4 axis (X, R, Z1, Z2), 6 axes (X1, X2, R1, R2, Z1, Z2,) back gauge options with servo motors.

- Possible to upgrade the choice of optional equipment with different controller options.

- Automatic axis referencing when machine is turned on.

- Side guards are standardized according to CE standards.

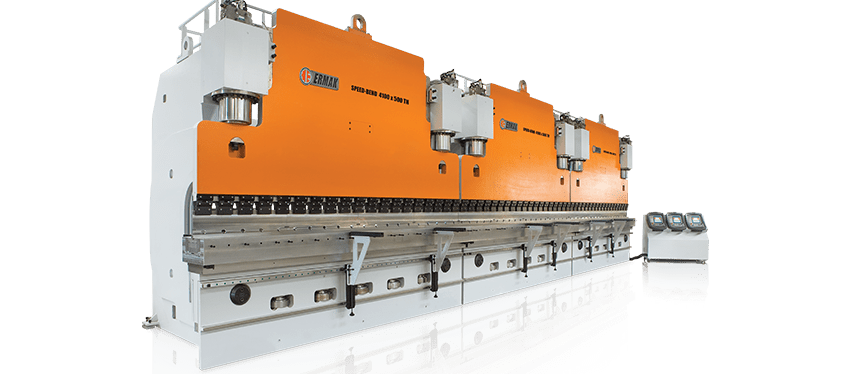

- User-friendly, ergonomic, mobile control unit designed for tandem applications.

Perfect design in every aspect;

ERMAKSAN improves its reliability every day by working with highly educated engineers and

by using the latest technology in a rapidly developing sheet metal industry.

ERMAKSAN improves its reliability every day by working with highly educated engineers and

by using the latest technology in a rapidly developing sheet metal industry.

No sheet plate can stand this power

- Wider Bends

- Deeper Bends

- More Powerful Bends

- High quality and repetitive bending is obtained by using synchronized cylinders and valves.

- Automatic axis referencing and calibrating at very first time when machine is turned on.

- All ERMAKSAN machines are designed by using SOLID WORKS 3D programming and made by enhanced ST44-1 quality steel with the latest technology.

- World wide recognized long lasting, stiffened, precise top and bottom tools.

- Silent high pressure pump.

No sheet plate can stand this power;

Heavy Duty Press Brakes are an excellent machine with superior performance and deep bending capacity to be used for years.

Heavy Duty Press Brakes are an excellent machine with superior performance and deep bending capacity to be used for years.

HiPerfect configuration with 6 axes back gauge;

Make your heavy duty bending perfect thanks to variable, customized and easy to use back gauge configurations.

Make your heavy duty bending perfect thanks to variable, customized and easy to use back gauge configurations.