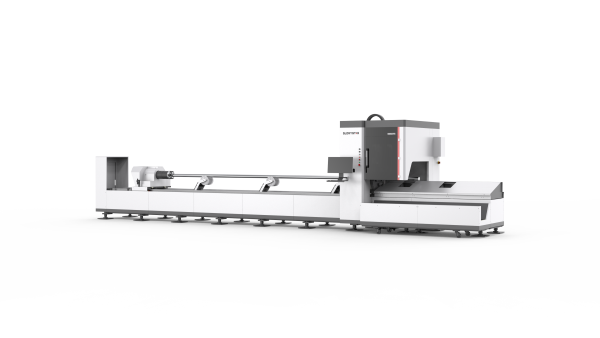

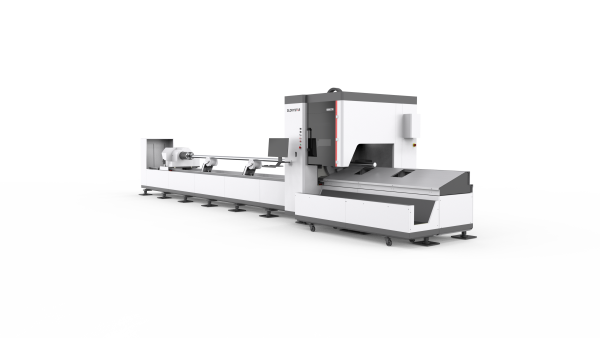

Description

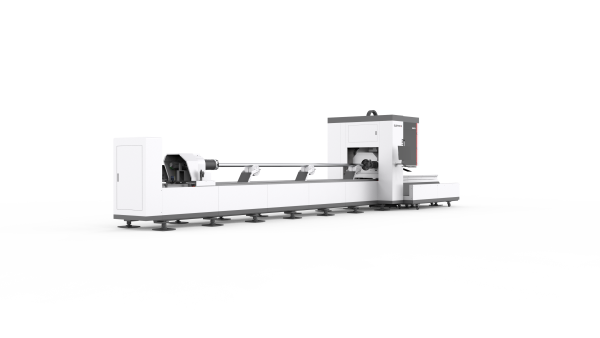

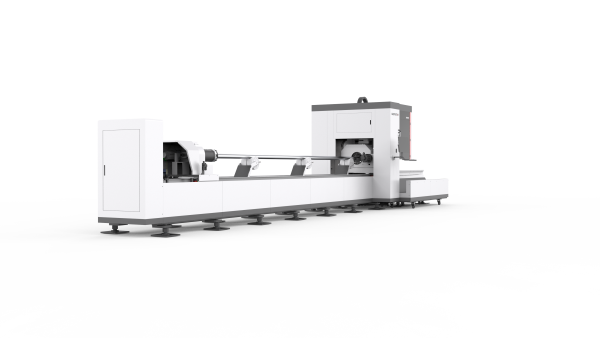

| Chuck with the highest standards in the industry:

High security -Large inner hole of chuck, high safety for automatic loading & unloading. |

|

| Less inertia – Creates high-speed processing and allows the rapid cutting of small pipe fittings Less tailing – The material can reach the front chuck as far as possible to realize ultra-short tail cutting Strong clamping force – The claw adopts a special friction surface to ensure that the clamping pipe does not slip off High rigidity – Barrel structure design, high supporting rigidity and strong stability Shaped tube clamping – With dedicated jaws, it can clamp non-closed pipes, such as channel steel (C-shaped steel), I-beam (H-shaped steel). Optional double-row roller jaws for efficient cutting of very small tubes (10~30 mm) |

|

| Efficient automatic unloading:

The two variable diameter wheels at the blanking place automatically rise and fall, supporting the workpiece when rising, and the workpiece slides down automatically when falling, greatly improving productivity. |

|

| Optional Automatic Loading System:

|

|

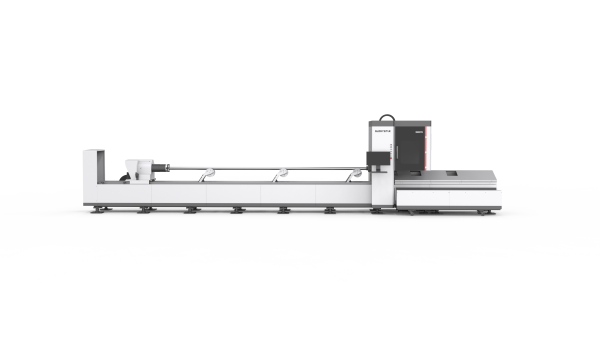

| Machine can support the following:

square pipe with a side length of 15-150mm round pipe with a diameter of 15-210mm special-shaped pipe processing such as channel steel (C-shaped steel), I-beam (H-shaped steel), etc. The cutting shape is complete, meeting diversified processing needs, ultra-high cost performance. |

|

| Dust removal system:

The dust removal system is independently researched and developed by Glorystar Laser. Ventilation design inside the chuck and inside the pipe to reduce the slag hanging in the pipe |

|

| Feature/Model | GS-6022TG | GS-6032TG |

| Chuck specifications | 220 | 320 |

| Through-hole diameter (mm) | 225 | 325 |

| Processing range(mm)

Circle tube Square tube Rectangle tube |

15-210

15-140 160*80 |

15~320

15~220 300*100 |

| Maximum tube cutting length | 6000mm*φ220mm | 6000mm*φ320mm |

| Repeated positioning accuracy | ≤0.03mm | ≤0.03mm |

| Positioning accuracy | ≤0.05mm | ≤0.05mm |

| Maximum positioning speed | 100m/min | 70m/min |

| Maximum acceleration | 1G | 0.7G |

| Maximum speed of chuck | 100r/min | 60r/min |

| Tube weight | ≤240kg | ≤450kg |

| Machine weight | 5.5t | 6.3t |

| Covering area | 11380mm*2000mm | 11000mm*3000mm |