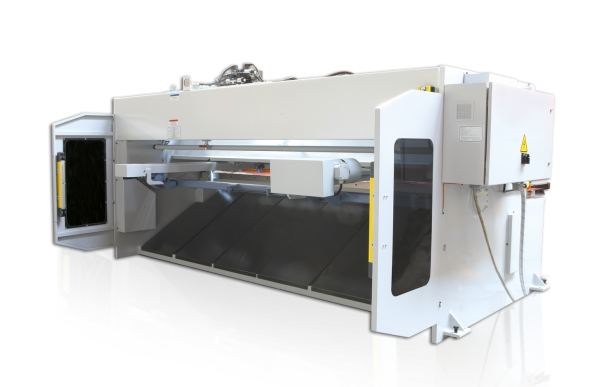

Description

ERMAK HGS Series are high performing and economic machines with modem design, strong steel weld construction frame and perfect cutting quality. Available dimensions are 2600, 3100, 4100 mm and capacities are 6 mm, 8 mm. Main frame and top beam are in box construction and highly resistant to twisting forces. Fast and precise blade gap adjustment system is placed on the right side of the machine. Blade gap adjustment for high quality cutting could be made without any step and from a single point. HGS Series shears are the best performers in their category with 18-20 strokes per minute in full length.

STANDARD EQUIPMENTS

- Hardened blades: Top blades : 2 sides,Bottom blades : 4 sides

- ERCUT 7 controller or Cybtouch 8

- 1000 mm motorized backgauge system with 0,1 mm accuracy.

- 1000 mm side gauge and front support arms.

- Metric and inch rulers.

- Roller bearings on the front support arms to easy placing sheets.

- Front, side and back safety panels which are suitable for CE norms.

- Rear light curtains for safety.

- Sheet sliding system.

- SIEMENS electrical system.

- Hoerbiger hydraulic system.

- Automatic hydraulic blade gap adjustment.

- High pressurized silent pump.

- Hold down cylinders.

- Moveable foot pedal.

- Emergency stop button.

- Shadow line.

- Collapsible finger protection.

OPTIONAL EQUIPMENTS

- Front angle gauge.

- Side gauge and front support arms in optional lengths.

- Sheet support system for thin sheets.1- Pneumatic support system. (Lever type)

2- Pneumatic support system. (Monoblock panel type) - Hydraulic oil cooling and heating system.

- Optional solid table.

- Stainless steel blades.

- Ability to increase stroke amount per minute.

- Light safety system for finger protection.

- Coolant system or heater can be placed in electric panel according to ambient conditions.

- Double foot pedal.

- Optional alternative colors.

- Electrical panel or controller can be placed on right side of the machine.

- Laser cutting line.

- Possibility to produce special size and capacity models due to your manufacturing needs.

- Optional alternative colors.